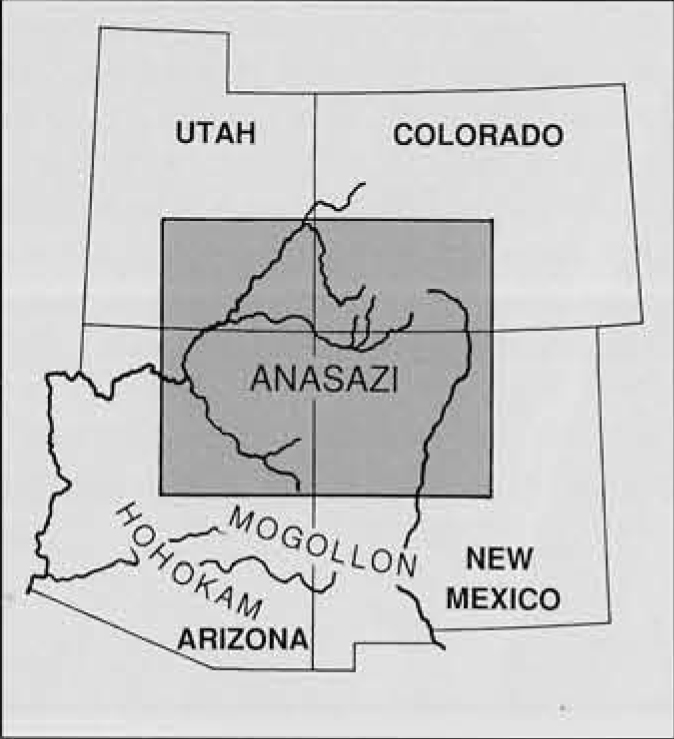

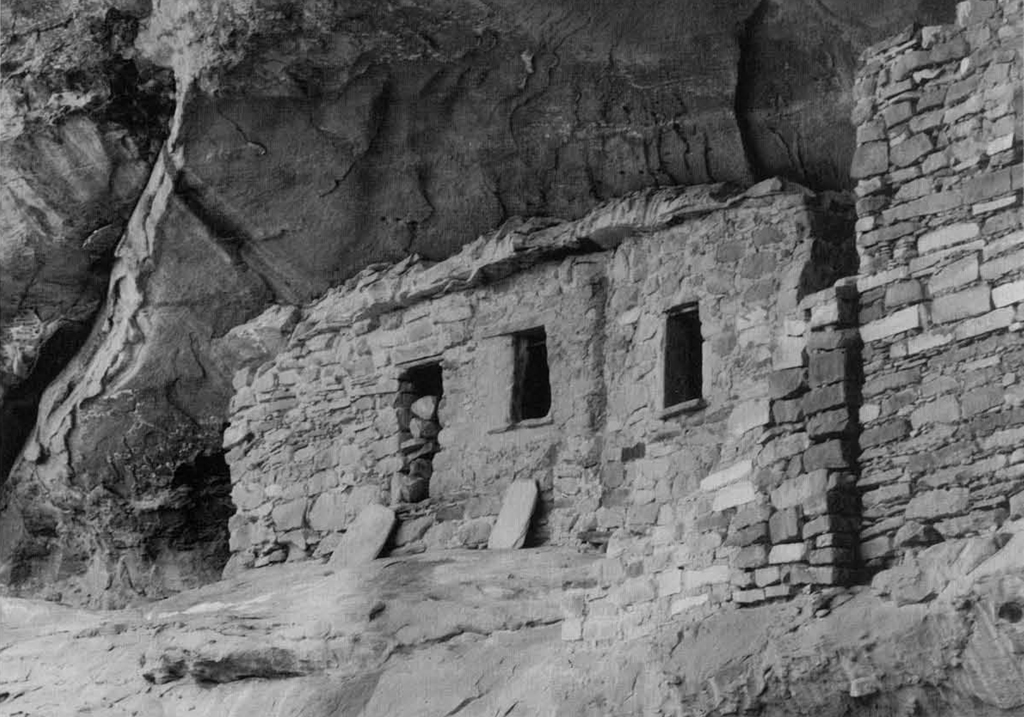

Pottery is ubiquitous on Anasazi archaeological sites (Figs. 1 and 2), and it is both one of the aesthetic joys and most powerful tools of the archaeologist. The beauty of Anasazi pottery was one of the primary motivations behind the early archaeological expeditions to the Southwest; the shelves of museums are stocked with exquisite display specimens. But as this motivation was satisfied, and as knowledge about the inner workings of ancient cultures became more important, pottery was seen in a different light. Consistent progressions of decorative style were defined across the region with the help of stratigraphy and tree-ring dating, and those styles in turn became the basis for one of the most precise ceramic chronologies in the world. Simultaneously, geographic variations in raw materials were documented and became the basis for studies of prehistoric exchange networks. These two aspects of Anasazi pottery are now nearly taken for granted in Southwestern archaeological research, and attention is once more being directed toward pottery itself. However, instead of its beauty, archaeologists are now studying pottery technology: its origins, changes within the craft, and the organization of pottery production within Anasazi society.

Anasazi Pottery

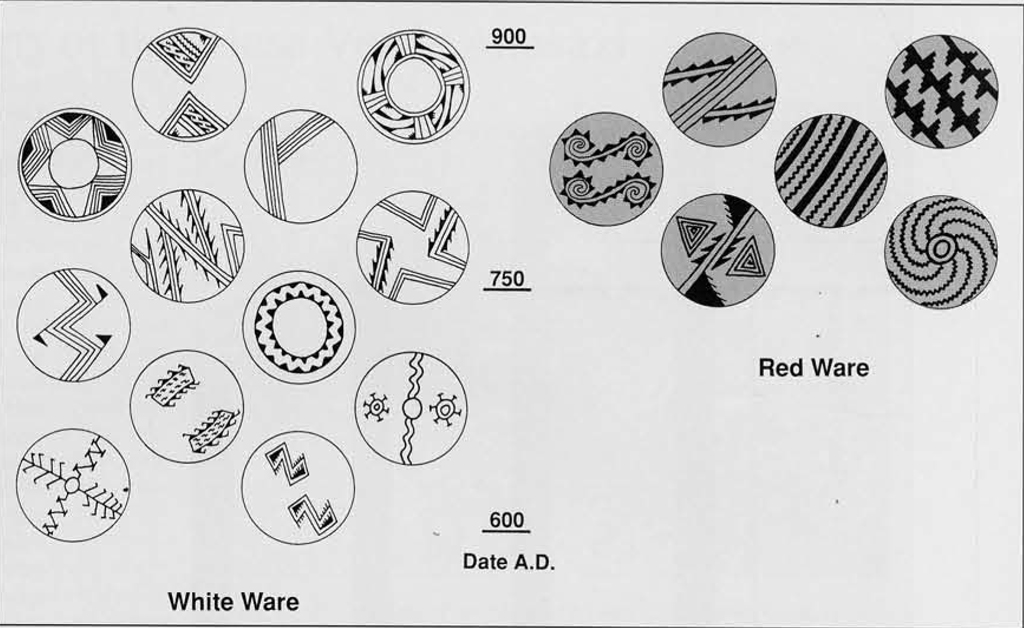

Anasazi pottery is distinguished from that of other Southwestern culture areas by its predominant colors (gray, white, and red), a coil-and-scrape manufacturing technique, and a relatively independent stylistic trajectory. Speculation about its origin has centered around diffusion from Mogollon and ultimately from Mesoamerican cultures to the south, but the stark contrasts between Mogollon brown and Anasazi gray and white pottery have also raised the possibility of independent invention through accidental burning of clay-lined baskets (Morris 1927). However, the contrasts are usually drawn between fully developed examples of both Mogollon and Anasazi pottery traditions (Fig. 4). Recent research by Dean Wilson and colleagues has pointed to underlying similarities of the earliest pottery throughout the upland Southwest (Wilson and Blinman 1991; Skibo et al. 1992).

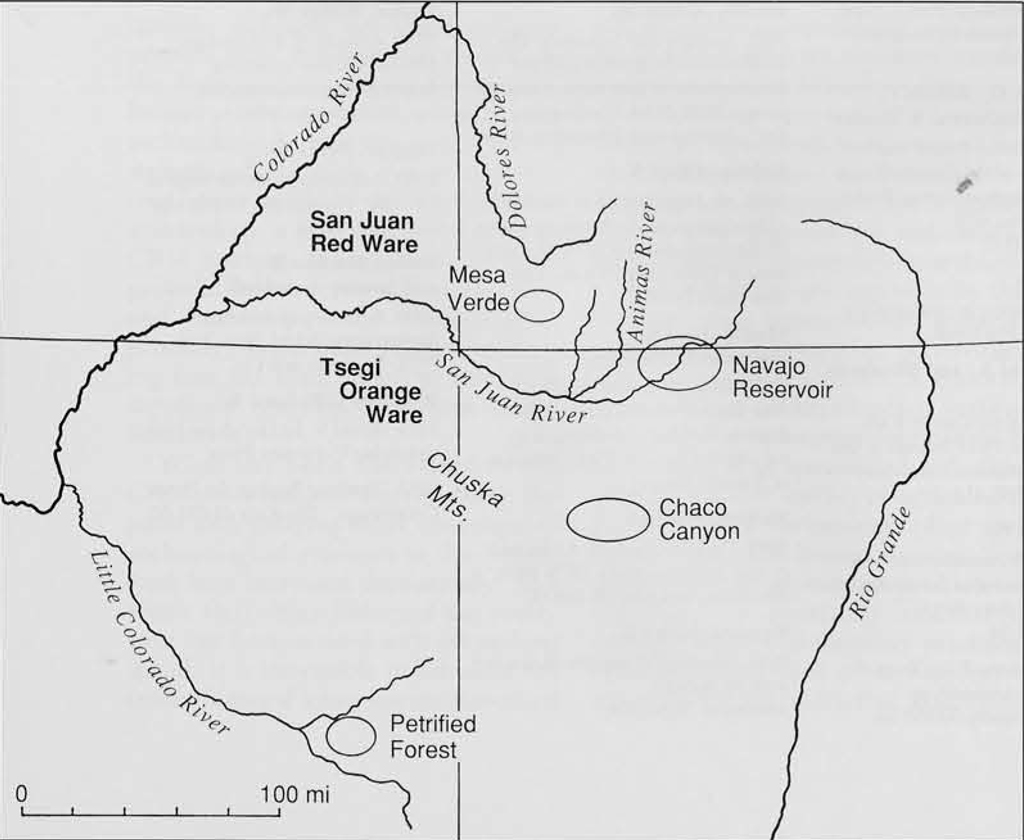

Pottery occurs as early as A.D. 200 in the Anasazi region, and most of this pottery appears to have been made of floodplain or soil clays. These alluvial clays are often usable as they come from the ground, and the high iron content of the clay resulted in a brown surface color. An open fire on the ground surface would have proved adequate for firing. The best known of these early pottery sites are in the Petrified Forest National Park and the Navajo Reservoir area of northern New Mexico, where a crumbly brown ware is present on sites dating within the A.D. 200-500 period. By A.D. 500, the durability of the brown ware improved, and it was joined by a gray ware pottery. By A.D. 600, Anasazi potters focused their attention on the gray ware technology, and brown wares were no longer manufactured.

The transition to Anasazi gray wares appears to have resulted from the adaptation of brown ware production techniques to new raw materials. As the brown ware technology moved northward from the Mogollon area, potters continued to seek out floodplain or soil clays, ignoring for a time the geologic clays that were abundant as shale layers within the sandstone cliffs of the Four Corners landscape. Most of these geologic clays have high shrinkage ratios, and potters would have had to modify the clays before use. Also, unlike the alluvial clays, the geologic clays appear to perform best when fired under neutral rather than the oxidizing conditions of an open fire. Experimentation with the geologic clays began in the 6th century, and by the beginning of the 7th century the technology had been fine-tuned, setting the stage for the next 600 years of Anasazi pottery production.

The Gray Ware Cooking Pot

The foundation of the Anasazi ceramic tradition was the cooking pot. As maize became a significant part of the Anasazi diet, boiling became increasingly necessary as a food preparation technique. Although food can be boiled in baskets, pottery vessels have a number of advantages: pots are less time-consuming to produce, fuel use is more efficient, and the same container can serve for dry storage, wet storage, and cooking. Pots are brittle, however, and better suited to sedentary rather than mobile lifestyles. The Four Corners environment was perfect for feedback between agriculture, sedentism, and pottery technology, and pottery rapidly became an integral component of Southwestern culture (LeBlanc 1982).

Modern ceramic technology can be extremely intricate, producing products as diverse as building brick, porcelain, and space shuttle heat shields. In Anasazi culture, the initial goal was to produce a durable cooking pot. Although outwardly simple, the cooking pot is a delicate compromise between conflicting technological and functional demands. Anasazi geologic clays swell and shrink so much on wetting and drying that vessels of pure clay would crack prior to firing. Non-swelling material (temper) can be added to the clay to reduce and control shrinkage, but temper reduces the strength of the vessel wall. The potter can control the effect of temper on strength by altering the shape, size, and material of the temper particles. Angular tempers form stronger bonds with the surrounding clay, finer tempers distribute weaknesses more evenly, and tempers that have a similar coefficient of thermal expansion to that of the surrounding clay create fewer flaws during the high heat of firing and subsequent cooling.

Given a particular clay and temper combination, the strength of the finished vessel results from the permanent alteration of clay minerals by the heat of firing. This alteration follows a continuum from the initial destruction of the clay mineral structure (earthenware) to complete sintering or fusion of the clay minerals into a glass-like material (such as porcelain). The strongest pots are those where sintering has progressed the farthest, but those pots are also the most brittle.

Strength alone is not a good measure of cooking pot performance (witness the catastrophic result of placing a porcelain bowl on top of a gas burner). The most important selective pressure on cooking pot design is the contrast between the heat of the cooking fire (as much as 800° C) and the relative coolness of the vessel contents (usually less than 100° C). This difference places tremendous stress on the vessel wall, and success in dealing with this stress was the goal of early Anasazi potters.

The Anasazi compromise appears to have been coarse, relatively angular rock or sand tempers, coupled with firing regimes that achieved only low levels of sintering. These mineral tempers tend to expand more than the surrounding clay during firing, creating voids around the temper particles when the vessel cools, and the lower-fired clay creates a relatively soft vessel wall. Our understanding of why this combination works better than others is only now being tested in the laboratory, but the likely explanation is that the voids and lightly fused clay accommodate small failures as a means of relieving stress, as opposed to allowing stress to build to the point of catastrophic failure.

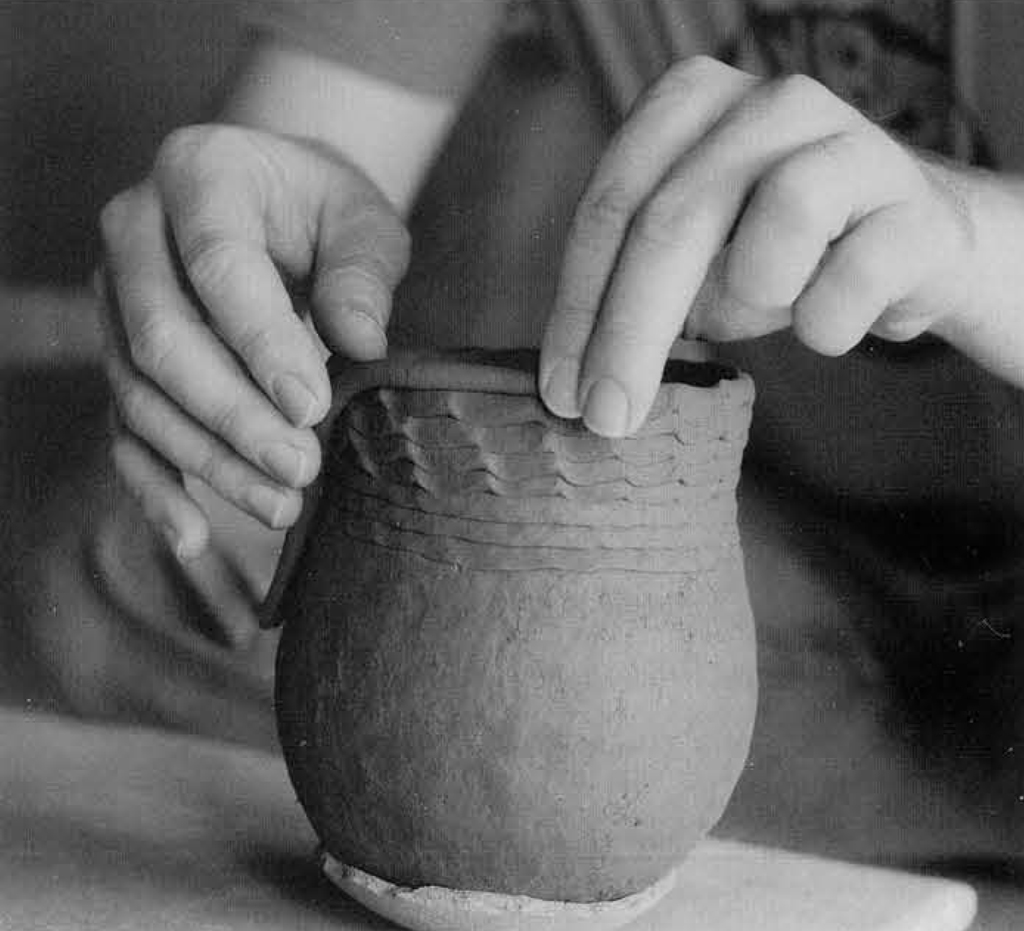

The formula for Anasazi cooking pot clays was achieved by A.D. 700 and remained stable for the subsequent six centuries of occupation in the Four Corners area. However, there were dramatic changes in the appearance of cooking vessels throughout this period (Fig. 5). Initially, the coils of clay that made up the pot were carefully scraped on both interior and exterior surfaces, welding coils together and creating plain surfaces. Prior to A.D. 700, and especially during the brown ware phase of Anasazi pottery development, these plain surfaces were then polished to greater or lesser degrees. By A.D. 700, polishing ceased and most cooking jars were left plain. By the late 8th century, potters began to leave unobliterated coil junctures on the exteriors of the vessel necks, creating a neckbanded appearance. In the early 10th century, some neckbands were rhythmically indented, creating a corrugated appearance. At first these surface treatments were confined to the neck region of the vessel, but by the late 10th century entire cooking jar exteriors were covered with corrugations. Corrugation became the norm for most Anasazi cooking jars from this time through the 13th century abandonment of the Four Corners area.

Neckbanding and neck corrugation have been interpreted as stylistic expression, but Southwestern archaeologists have suspected that a functional explanation underlay the adoption and persistence of all-over corrugation. The basis for this suspicion has been the assumption that corrugated textures should be time consuming toe produce, and that such an investment by the potter must have been justified by more than aesthetics. This view is further supported by the expectation that the strength of corrugated jars would be slightly less than plain jars due to the lack of a strong coil weld on the exterior. Why make a more expensive and weaker pot for looks alone?

Possible functional explanations offered for corrugation have included a better gripping surface for carrying, better heat transmission, and better resistance to failure due to the stress of cooking. These and other possible explanations can only be tested by experimentation, but however entertaining such experiments are for the archaeologist, results must be interpreted with caution. Archaeologists can control some aspects of raw material, technique, and technology, but we will never know how closely we have approximated the decisions and actions of Anasazi potters and cooks.

Experimental research has been conducted on two aspects of corrugation and is being conducted on others. Studies by Lisa Young and Tammy Stone (1990) measured the rate of heating with plain and corrugated replica vessels. They failed to find any heat transfer advantage of corrugated over plain surfaces, and the results actually suggest that plain vessels conduct heat more quickly.

As part of another set of experiments, corrugated and plain vessel replicas were made using the raw materials and techniques of northern Anasazi potters (Fig. 6). Vessel production was timed, and the surprising result was that it takes about one-third less time to produce a corrugated vessel than to obliterate the exterior coil junctures of a plain pot. Anasazi potters could make more pots in less time by adopting corrugation. However, too many complications and questions remain to believe that this is a sufficient explanation for the popularity of corrugation. Experimental research is continuing on the effects of corrugation on vessel strength and resistance to heat stress.

Decorated White Wares

Although the need for cooking jars is assumed to have been the driving force behind the early development off Anasazi pottery, once in place, the technology was adapted to the product lion of serving bowls and storage jars Most of these were decorated forms it which a painted design was fired onto the surface of the vessel. Painted decoration was poorly suited to the earl) brown wares, but the gray to white background of the geologic clays provided a good contrast for dark pigments. These “white” wares appeal almost simultaneously with the initial exploitation of geologic clays for cook ing jars (prior to A.D. 600).

Initially, the only differences be tween gray and white ware vessels were the choices of vessel form and the application of painted decoration to the latter—clay, temper, and firing were similar. Soon, however, Anasazi potter: must have realized that there wen fewer functional constraints on white wares since the vessels did not have to withstand the rigors of cooking. Thee first departure from gray ware technology was the grinding of finer temper making it easier to produce smooth surfaces for painting and increasing the strength of the vessel wall. This change took place sporadically through the 7th century and was widespread by A.D. 800.

The second change was experimentation with alternative tempering materials, principally the use of crushed potsherd (grog), beginning in the late 9th century. Potsherds became readily available as the Anasazi became more sedentary. Sherd temper retained the advantages of angular particles while adding the advantage of having a coefficient of expansion similar to that of the surrounding clay. A white ware vessel tempered with finely crushed sherd would be a stronger vessel than its contemporary cooking pot. Not all Anasazi white ware potters switched to sherd temper, but many had done so by A.D. 1000, much to the chagrin of archaeologists who source pottery by variations in rock temper in order to study exchange networks.

A third change was an increase in firing temperature and duration. This change is measurable as slightly increased sintering in white ware sherds dating to the 8th and 9th centuries, and a dramatic increase in both sintering and vessel wall thickness at about A.D. 1100. Sintering increases both strength and brittleness, but potters offset the brittleness with an increase in wall thickness. These changes in firing correlate with the widespread adoption of trench kills (see box) by Anasazi potters in the Four Corners area.

Three classes of pigments were used in white ware production. The first includes iron- or manganese-rich minerals. These were powdered, painted on the vessel with the aid of a sticky plant syrup or binder, and fused to the vessel on firing. If the firing was successful, a black design resulted on a gray or white background. If the firing was less successful, the design could be brown or red, or it could fail to fuse. The second class of pigments is a subset of minerals with enough lead to serve as a fluxing agent, producing a glaze paint. These were never applied as an overall surface cover in the sense of our modem glaze pottery but only as a pigment for the limited areas of painted designs. Whereas mineral paints were used through the entire sequence of Anasazi pottery production, glaze paints were used only until about A.D. 850 and only in the Animas River area of southeastern Colorado.

The third class of pigments is organic or carbon-based. These consist simply of a plant syrup that soaks into the clay and carbonizes within the vessel surface during firing. Successful use of this pigment requires careful control of firing and may also be dependent on the type of clay used. Organic paints occur throughout the Anasazi sequence in some areas, but they become the most popular paint after about A.D. 1100. Mineral and glaze pigments are relatively insensitive to firing conch-lions, but if too much oxygen is present near the vessel surface during firing, organic paint will burn out (oxidize), effectively erasing the design.

Red Ware Production

Although the Anasazi culture area is defined in large measure by gray and white ware pottery, red ware technologies were also developed (Fig. 3). Early Mogollon potters produced red-slipped brown wares, and a few unpainted, red-slipped bowls occur in Anasazi sites dating to the late 7th century. These bowls were manufactured by coating a gray clay body with a red clay slip, and firing the vessel in a neutral to oxidizing atmosphere to preserve the red color. Although made throughout the Anasazi area, these slipped red vessels were so rare that most of the early Anasazi potters were content with dusting the outside of some of their fired vessels with powdered hematite, giving the pots a temporary or “fugitive red” blush.

A more elaborate red ware technology was developed by potters in southeastern Utah around A.D. 750, marking the start of the San Juan Red Ware tradition. This ware shared tempers and vessel forms with contemporary white ware technology, but red wares were an extreme departure in both firing regime and decorative style (Fig. 7). The foundations of the technology were iron-rich, gray geologic clays. These clays could yield gray or white ware vessels if fired in a neutral atmosphere, but they would turn bright orange or red if they were strongly oxidized during firing. At first, designs were applied with deep red pigments, but black or dark brown pigments were used exclusively by A.D. 800. Light slips of very high-iron clays were applied to increase the intensity of the red surface color, and heavier slips, that produced a deep red surface became, common after A.D. 900.

The vast majority of red ware production remained concentrated in southeastern Utah until about A.D. 1050. At that time red ware production shifted south of the San Juan River into northern Arizona. This coincided with a change in temper selection from crushed rock to crushed potsherd, and these changes define a new ware, Tsegi Orange Ware. Potters added to the design repertoire by using the red slips to define parts of the design and by making use of white as well as black paint, resulting in a palette of orange, red, black, and white. Production of Tsegi Orange Ware continued through the abandonment of the Four Corners area, but its production volume shrank as another red ware, White Mountain Redware, was traded into the Four Corners area from the south.

Organization of Production

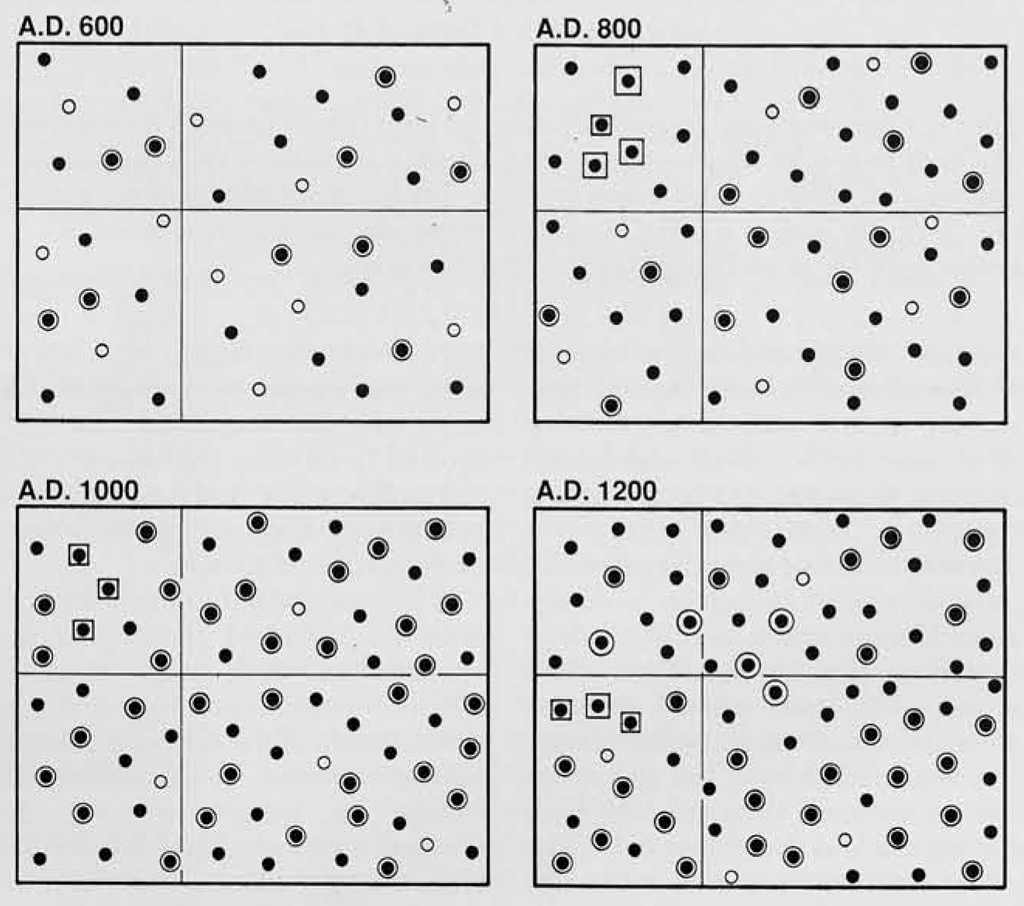

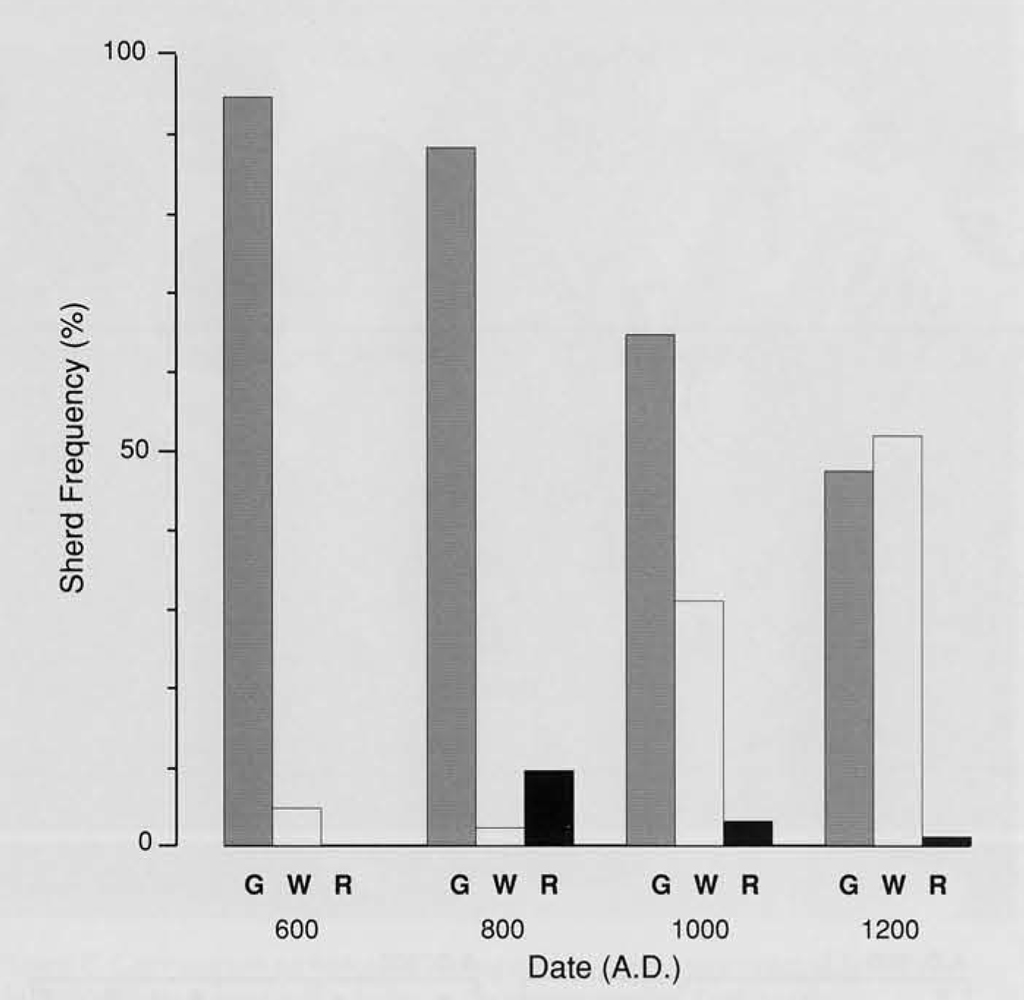

The technological innovations of Anasazi pottery occurred in a setting of changing production organization (Fig. 8). It is clear from the slow beginnings of pottery production that not all households made their own pottery, and even as late as the end of the 8th century there are households that appear to have obtained most, if not all, of their cooking pots by exchange (Wilson and Blinman 1991). However, village life and agricultural intensification in the 9th century appear to have sparked an increased demand for vessels that was met by household production. With only a few exceptions, gray ware potters were present in most households through the remainder of the Anasazi occupation of the Four Corners area. One of the more interesting exceptions is the large scale importation of cooking jars into Chaco Canyon from the Chuska Mountains area, more than 60 kilometers to the west (Toll 1984).

White ware production appears to have been somewhat specialized throughout the Anasazi sequence and was probably in the hands of a few skilled individuals. Evidence for this consists of concentrations of white wares at particular sites (presumably potters’ residences), and a tendency for less diversity in white ware than gray ware clays and tempers. An increase in the overall volume of production by white ware potters occurred after A.D. 1000 (Fig. 9), but the only strong evidence for mass production consists of the trench kilns at are abundant after A.D. 1100. Many of these kilns are more than 5 meters long, and a single firing would have yielded enough pottery for many households.

The red wares constitute the clearest case for specialized ceramic production. Within 30 years of their introduction, red ware vessels were being traded from southeastern Utah across the Mesa Verde region and beyond. The volume of production and exchange was so great that white ware production was temporarily suppressed over much of the Mesa Verde region through the early decades of the 9th century. Production and exchange continued at a slower pace through the end of the 9th century, waxing and waning with regional cycles of village formation and abandonment (Orcutt et al. 1990). White ware production slowly returned to prominence in the 10th century as red ware production declined, and there was a slow stylistic convergence between the two wares. After the shift of the red ware production to the Kayenta region, red ware exchange into the Mesa Verde region declined, becoming insignificant after specialized white ware production reached its peak.

Conclusion

Our perception of Anasazi pottery has changed over the past century. Aesthetic appreciation of pottery has been augmented by its use as a research tool, allowing us to date sites with tremendous precision, and forming the basis for elaborate reconstructions of trade and exchange. Now the attention of the archaeologist is also focusing on pottery as a technology, and we are beginning to understand the sophistication of the Anasazi potter, as scientist, artisan, and entrepreneur. Ink this context, pottery becomes a physical record of the changing economic and social forces that shaped the fabric of Anasazi life, adding another dimension to our understanding of the past.

Kilns of the Mesa Verde Anasazi

Through the early 1970s, reports of Anasazi kilns had been limited to occasional speculation about the function of unusual features on a handful of archaeological sites (e.g., Morris 1939). This situation has changed rapidly in the past two decades, with the recognition of trench kilns by the hundreds across the Four Corners area. The first of these was reported by Claudia Helm and coworkers while describing archaeological remains in the path of highway improvements in southeastern Utah (1973). They had encountered a shallow stone-lined trench, not unlike the footings for an Anasazi room block, but its shape and size were just unusual enough to raise doubts about an architectural interpretation. While preparing their report, they reached the conclusion that it could not be a room foundation, and they suggested that it might have been a kiln.

This report languished in the “gray literature” of contract archaeology until the early I 1980’s, when a set off five similar features were uncovered by the construction of a well pad in southwestern Colorado (Fig. 10; Hibbets and Harden 1982). This time, one of the features included abundant warped and overfired pottery—the wasters and cover sherds of pottery firing. The report of this find spread rapidly among Four Corners archaeologists (Fuller 1984), and in the intervening years hundreds of these trench kilns have been recognized and recorded in Utah, Colorado, and New Mexico.

These features range from 80 to 120 centimeters in width and 10 to 30 centimeters in depth, but they can be anywhere from 1.5 to 8 meters long. They are located away from residential sites, often several kilometers from the nearest settlement, and this great distance provides a partial explanation of why it took so long for archaeologists to recognize these features. Only rarely is pottery present in the kiln fill, but the trenches usually contain abundant blackened rock and charcoal overlying an irregular floor. The vast majority of these kilns postdate A.D. 1100, but one may date as early as A.D. 800, while another may date shortly after A.D. 1000. When pottery is present it is dominated by white ware vessels, and this type of kiln may have been designed specifically (but not necessarily exclusively) for the production of that ware.

Enough trench kilns have been excavated for us to be confident of their form and function, but we do not as yet know how they were being used to produce pottery. In an effort to resolve this question, Crow Canyon Archaeological Center (Cortez, Colorado) and the Museum of New Mexico (Santa Fe) have been sponsoring a series of workshops and experiments. These experiments have brought together archaeologists and potters in an effort to replicate firing regimes that could have,. been used by the Anasazi potters. Results to date are’ getting closer and closer to the prehistoric examples (Fig. 11), but they still lack the consistency and clarity of color that was achieved by the Anasazi potters.